Quality Control: Engineering, Production & Inspections

Quality Control in Engineering:

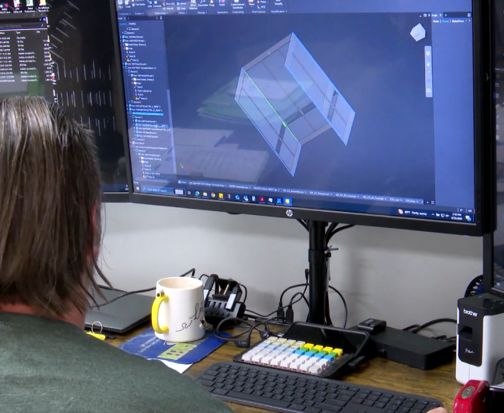

Most errors occur during the engineering phase, which is why IDEC is developing automated 3D models driven by Excel inputs. By entering key values into a spreadsheet, all model components are auto-generated and updated, reducing manual mistakes and significantly speeding up production planning. Standardized listing layouts ensure that all shop personnel work from the same reference, improving clarity and consistency. When issues are identified in production, the core model is updated to prevent repeat errors on future listings, creating a continuous improvement loop in the engineering process.

Quality Control in Production:

Quality assurance begins the moment materials arrive from our vendors, with all incoming items thoroughly inspected before being accepted into production. Machine operators are trained to identify and stop any defects before passing materials to the next station, and each operator is assigned a unique colored dot label. As parts move through production, these labels create clear accountability, allowing any defect to be quickly traced back to the exact station or operator for fast resolution. Whether the issue stems from a tool or a handling error, it is addressed immediately. Additionally, all tools used in production are routinely inspected, and any defective equipment is replaced without delay to maintain precision and safety.

Final Inspections:

Every entrance is thoroughly inspected prior to packaging and crating to ensure that quality and finish meet IDEC standards. All cabs are assembled and stood upright for a complete final inspection, during which a formal inspection checklist is completed. Any issues identified with an IDEC product are resolved immediately before it leaves the facility, ensuring that only top-quality components are delivered to the customer.